Product Applications Advantages of CRFs

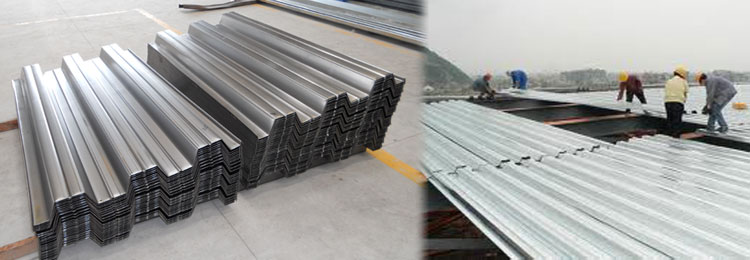

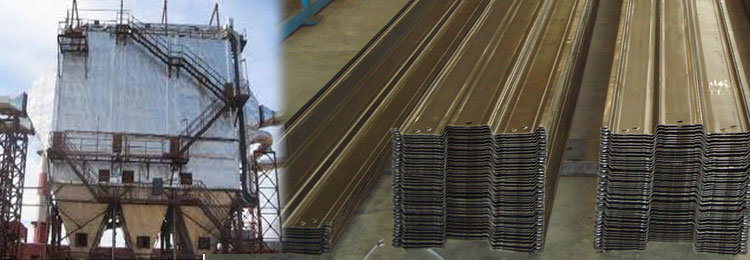

Cold Roll Formed Sections are made by passing metal in coil / sheet form through a series of profiled rolls. The stages vary based on the shape of the profile and the thickness of the metal required. Cold Roll Forming enhances the tensile strength of the metal at every stage of forming.

Cold Roll Forming is ideally suitable for:

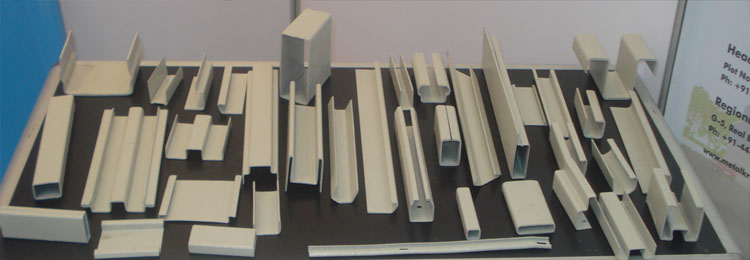

- Complex cross-sections of profiles.

- Lengthy profiles.

- Mass production.

- Consistency and repeatability.

The cold roll process scores over the conventional press-breaking method, as the sections are gradually formed and are free from stresses. Beside, the cold working induces additional strengths, which is beneficial for load-carrying members.

The continuous production process gives uniform cross sectional dimensions through the length of the profile. It ensures a high degree of accuracy, and can be made to close tolerances. Introducing additional bends also increases the rigidity of the section.